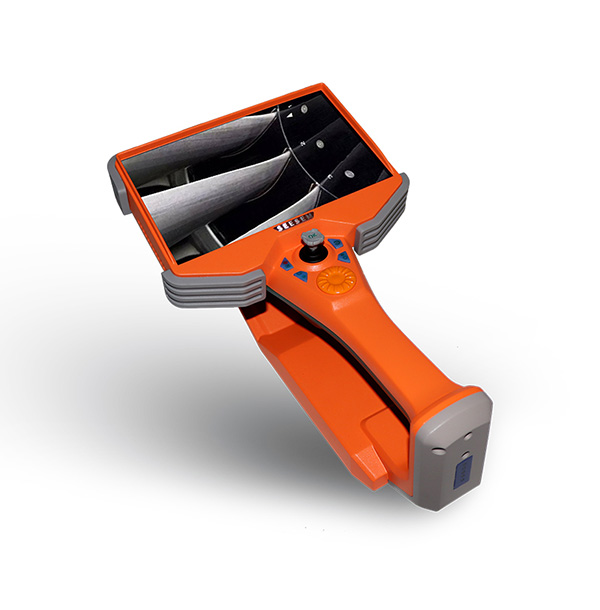

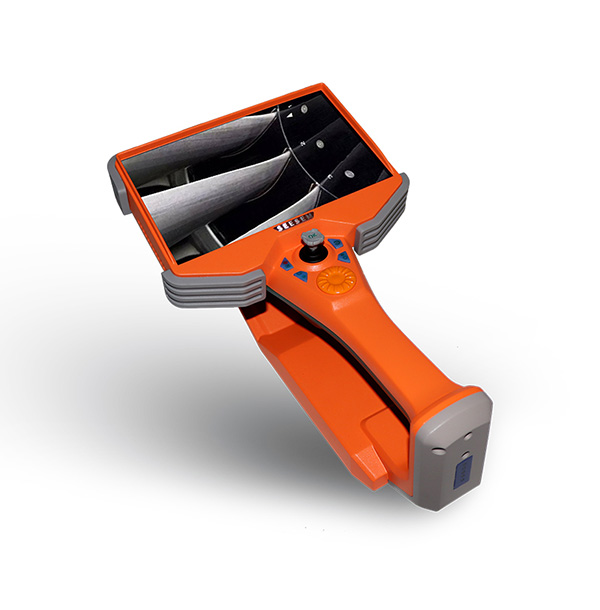

Video borescope with AI

Waygate Technologies, a Baker Hughes business, is upgrading its high-end Everest Mentor Visual iQ (MViQ) VideoProbe for remote visual inspection. The software upgrade enables Waygate Technologies, a world leader in industrial non-destructive testing (NDT) solutions, to offer one of the most advanced video borescopes with built-in artificial intelligence (AI) to various industries such as aerospace, energy and petrochemicals.To get more news about

industrial videoscope, you can visit seesemborescopes.com official website.

With the all-new MViQ OS 3.6 operating system, which includes several new significant features and applications, the company is utilising AI to assist inspectors in automatic defect recognition (ADR) for visual inspection. It also introduces the data management platform InspectionWorks, a solution to not only efficiently acquire, store and analyse visual inspection data, but also act on insights gained from the data across the entire lifecycle. Rather than just detecting defects in critical assets, this enables customers to avoid them entirely by improving processes, workflows and product design.

All MViQ users are able to upgrade their MViQ devices to the latest software version through the over-the-air (OTA) update service on a connected device or by going to the company’s InspectionWorks Store at inspectionworks.com All new features are automatically enabled on the device for a 90-day trial period, after which selected upgrades can be purchased.

The on-board analytical capabilities of Everest Mentor Visual iQ streamline the inspection workflow and further improve probability of detection (POD) for industrial assets by 150% compared with the previous MViQ OS. To increase inspection output and make processes more efficient, ADR minimises human error rates through intelligent training, as it automatically detects and characterises defects in real time.

In collaboration with Aiir Innovations, Waygate Technologies’ MViQ borescope now offers a solution for the identification and classification of defects directly on the device. The Aiir Lite analytic is a standalone still image version of Aiir’s artificial intelligence analytic. It comes in two variants: Aiir Lite Rotate for airfoil surfaces and Aiir Lite Combustor for the hot section. Both analytics enable the detection of defects in common commercial aircraft engine types. Via the InspectionWorks ecosystem, analytics can be deployed to the borescopes, placing AI and ADR at the fingertips of the end-user. By providing technology that assists with this kind of defect detection, inspections become faster and more reliable, while uptime of the asset is increased.